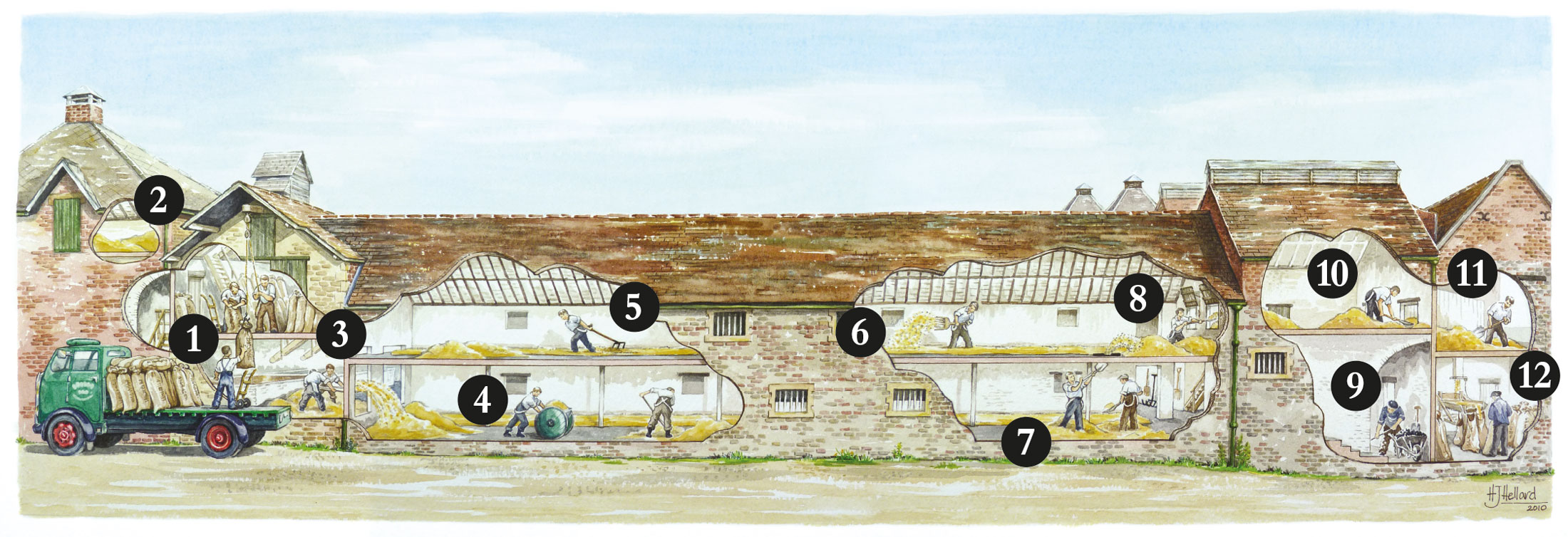

THE TRADITIONAL MALTINGS PROCESS

The age old tradition of Floor Malting has been preserved at Warminster Maltings.

The only changes are the initial delivery, the barley arrives on bigger trucks and the packing is state of the art, but everything in between stays the same.

Ploughing, turning and transferring from floor to floor is all done by hand at the only working maltings in the West of England.

How it works – based on our photographs from 1950

1 – HOISTING THE SACKS OF BARLEY INTO THE BARLEY STORE

Typically delivered via loads of 7 tons (70 x 4 bushel sacks) accurately weighed by the farmer when the sacks were filled.

2 – BARLEY DRYING ON THE ‘SWEATER’ KILN

Variable moisture content of barley delivered from the farms had to be addressed for safe long term storage.

3 – SPLITTING THE WET BARLEY ONTO THE UPPER AND LOWER FLOORS.

Following steeping and resting in the ‘couch’ the wet barley is equally divided.

4 – TRANSPORTING THE WET BARLEY ACROSS THE FLOORS USING A ‘BOBY’ BARROW

The large circumference, narrow wheeled malt barrow was highly manoeuvrable.

5 – PLOUGHING THE ‘GREEN’ MALT

The maltster’s hand drawn ‘plough’ separates and aerates the ‘green’ malt in the advanced stages of modification.

6 – TURNING THE ‘GREEN’ MALT

Using a six pronged wooden fork the ‘green’ malt is turned in order to manage the temperature in the early stages of modification.

7 – TRANSFERRING ‘GREEN’ MALT FROM THE LOWER TO THE UPPER FLOOR FOR LOADING ONTO THE KILN

In 1950 there was no elevator, just continuous shovelling.

8 – LOADING THE KILN

Both floors had to be loaded onto the kiln bed, and levelled, as quickly as possible.

9 – FIREMAN STOKING THE KILN

Drying the ‘green’ malt took up to 72 hours in a two stage process when management of the heat was key to the colour and flavour of the malt.

10 – LOADING THE KILN INTO THE MALT STORE

This was a very uncomfortable job only partially helped by the large extractor fans (kilns 3 & 4) which had succeeded the conical roofs (kilns 1 & 2).

11 – FRESH MALT STORED IN THE MALT STORE

The upper floor of the store was sub-divided into storage bays, with two storage bays per kiln for two different grades/batches of malt.

12 – DRAWING THE FINISHED MALT INTO SACKS OFF THE MALT SCREEN

The malt screen separated the dried shoots, known as malt culms, from the malt grains, which were then weighed into 4 bushel hessian sacks for delivery to the brewery.

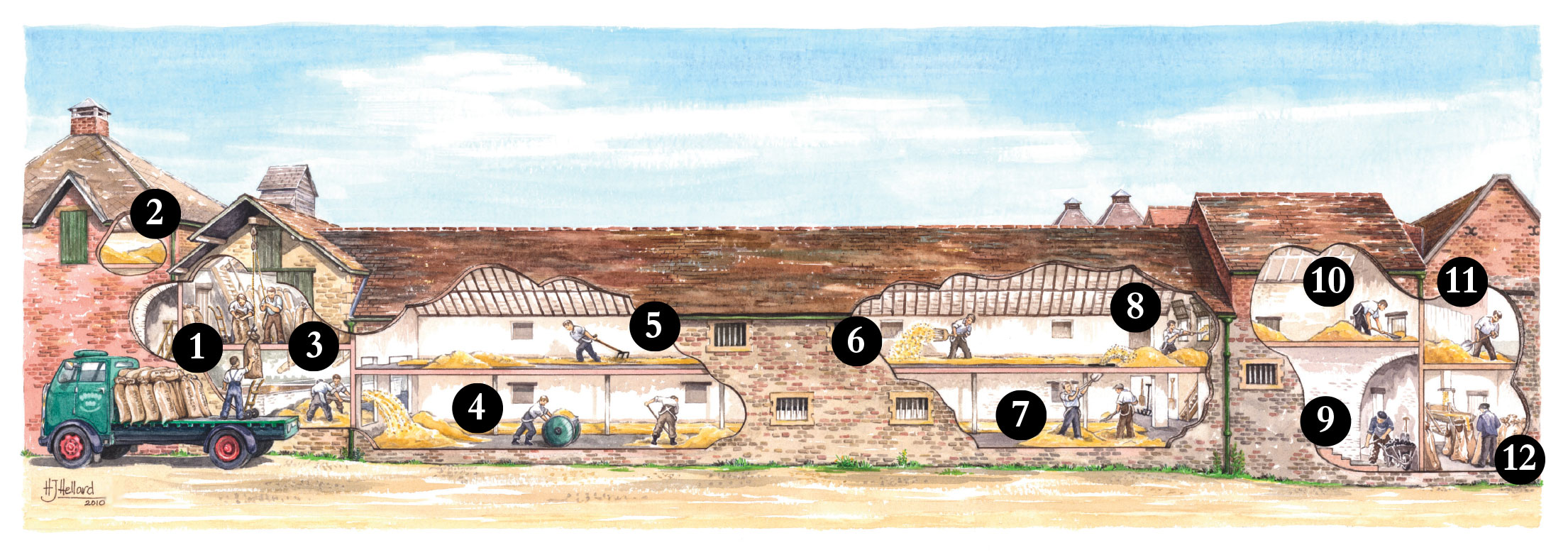

How it works – based on our photographs from 1950

1 – HOISTING THE SACKS OF BARLEY INTO THE BARLEY STORE

Typically delivered via loads of 7 tons (70 x 4 bushel sacks) accurately weighed by the farmer when the sacks were filled.

2 – BARLEY DRYING ON THE ‘SWEATER’ KILN

Variable moisture content of barley delivered from the farms had to be addressed for safe long term storage.

3 – SPLITTING THE WET BARLEY ONTO THE UPPER AND LOWER FLOORS.

Following steeping and resting in the ‘couch’ the wet barley is equally divided.

4 – TRANSPORTING THE WET BARLEY ACROSS THE FLOORS USING A ‘BOBY’ BARROW

The large circumference, narrow wheeled malt barrow was highly manoeuvrable.

5 – PLOUGHING THE ‘GREEN’ MALT

The maltster’s hand drawn ‘plough’ separates and aerates the ‘green’ malt in the advanced stages of modification.

6 – TURNING THE ‘GREEN’ MALT

Using a six pronged wooden fork the ‘green’ malt is turned in order to manage the temperature in the early stages of modification.

7 – TRANSFERRING ‘GREEN’ MALT FROM THE LOWER TO THE UPPER FLOOR FOR LOADING ONTO THE KILN

In 1950 there was no elevator, just continuous shovelling.

8 – LOADING THE KILN

Both floors had to be loaded onto the kiln bed, and levelled, as quickly as possible.

9 – FIREMAN STOKING THE KILN

Drying the ‘green’ malt took up to 72 hours in a two stage process when management of the heat was key to the colour and flavour of the malt.

10 – LOADING THE KILN INTO THE MALT STORE

This was a very uncomfortable job only partially helped by the large extractor fans (kilns 3 & 4) which had succeeded the conical roofs (kilns 1 & 2).

11 – FRESH MALT STORED IN THE MALT STORE

The upper floor of the store was sub-divided into storage bays, with two storage bays per kiln for two different grades/batches of malt.

12 – DRAWING THE FINISHED MALT INTO SACKS OFF THE MALT SCREEN

The malt screen separated the dried shoots, known as malt culms, from the malt grains, which were then weighed into 4 bushel hessian sacks for delivery to the brewery.