Welcome to Warminster Maltings where we still make malts the traditional way

What is malt?

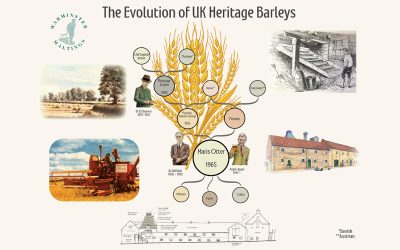

Malt is grain, mostly barley, which has been artificially germinated in order to convert it’s high starch content into a sugary substance which brewers, and distillers, can ferment to make alcoholic beverages.

We select our barleys by eye, and make our malts by hand. These are the procedures which have prevailed at our malthouses for more than 160 years, and are fundamental to their very special quality.

Sustainable, Resilient and Equitable!

Warminster Malts stand out for their very low carbon footprint. Barley grown sustainably on local Icknield soils, continues to be modified naturally by hand, just as it has been for more than 165 years. Our very traditional and visible procedures deliver both pronounced quality and character.

Sustainable, Resilient and Equitable!

Warminster Malts stand out for their very low carbon footprint. Barley grown sustainably on local Icknield soils, continues to be modified naturally by hand, just as it has been for more than 165 years. Our very traditional and visible procedures deliver both pronounced quality and character.

Floor Made – More Natural, More Sustainable

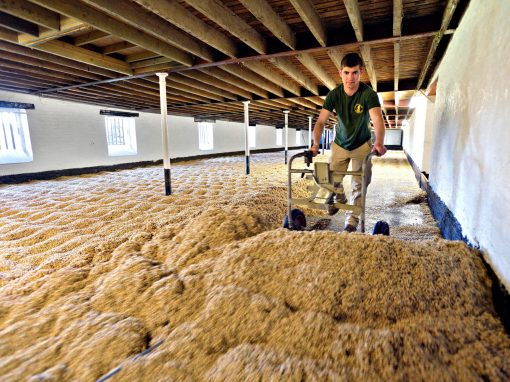

Like all food processing, slower is better. Our maltings was designed to follow gentle procedures, allowing for the optimum expression of the barley’s properties. Our germination floors are the perfect environment to optimize the ‘modification’ of the barley’s starch into the sugary substance called maltose.

Water comes from our own well, sunk deep below the malthouse into the chalk substrata. The temperature of this water is a stable 52F, winter and summer alike, perfect for the first stage of the malting process. Steeping the barley in water over 3 days is critical to triggering germination, the next stage in the process.

Ventilation and temperature control of the germination floors is vital to the ‘modification’ of the ‘green malt’. We work with the ambient temperatures, closing the window shutters when it is cold, and opening them when it is warm. The layout of the malthouses with its central wedge-shaped courtyard is a blueprint of the classic Victorian maltings. The complex was designed for purpose, exploiting nature’s elements.

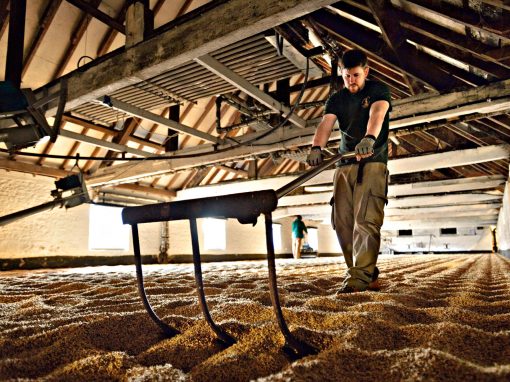

Passage of the green malt through the process still depends more on manpower than on fossil fuels. The maltsters are permanently armed with a malt shovel, from steep to kiln, with other hand tools (malt ploughs, turners and levellers) completing the inventory of processing aids. At Warminster, manpower is one of our most valuable, versatile and sustainable resources. It is why our customers refer to our team as “the Malt-Stars of Warminster”.

Robin Appel

Floor Made – More Natural, More Sustainable

Like all food processing, slower is better. Our maltings was designed to follow gentle procedures, allowing for the optimum expression of the barley’s properties. Our germination floors are the perfect environment to optimize the ‘modification’ of the barley’s starch into the sugary substance called maltose.

Water comes from our own well, sunk deep below the malthouse into the chalk substrata. The temperature of this water is a stable 52F, winter and summer alike, perfect for the first stage of the malting process. Steeping the barley in water over 3 days is critical to triggering germination, the next stage in the process.

Ventilation and temperature control of the germination floors is vital to the ‘modification’ of the ‘green malt’. We work with the ambient temperatures, closing the window shutters when it is cold, and opening them when it is warm. The layout of the malthouses with its central wedge-shaped courtyard is a blueprint of the classic Victorian maltings. The complex was designed for purpose, exploiting nature’s elements.

Passage of the green malt through the process still depends more on manpower than on fossil fuels. The maltsters are permanently armed with a malt shovel, from steep to kiln, with other hand tools (malt ploughs, turners and levellers) completing the inventory of processing aids. At Warminster, manpower is one of our most valuable, versatile and sustainable resources. It is why our customers refer to our team as “the Malt-Stars of Warminster”.

Robin Appel

Latest from the Malt-stars News

Edition 53: Friends of Warminster Maltings

English Whisky UpdateTwo reports landed in our Inbox at the beginning of June, one of which is the first report from the newly formed English Whisky...

Edition 52: Friends of Warminster Maltings

MaltingsFest 202418th - 20th April saw the return of the annual beer festival, MaltingsFest, which is held in Newton Abbott, Devon. It is now in its...

Edition 51: Friends OF WARMINSTER MALTINGS:

Dry January? Rain Free Summer!At Warminster Maltings we have had an amazing start to the year. Despite the widely reported 8% drop in “drinks sales”...

Edition 50: Friends of Warminster Maltings

New Year, New Hope, and New PricesWe can shout about the ‘New Prices’, because, contrary to almost anything else in our lives at the moment, from...

Edition 49: Friends of Warminster Maltings

Bonfire Night!On this day, 99 years ago, Warminster Maltings suffered a rather disastrous and costly event! There was a fire which, amongst much...

Edition 48: Friends of Warminster Maltings

We're On The Telly, Again!“A Cotswold Farmshop”, a new series on Channel 4, on Monday nights at 8 o’clock, began screening on Monday August 7th....